Custom Packaging Solutions That Work as Hard as You Do

At Commonwealth Packaging Corporation, we don't just make boxes—we solve business challenges. From protecting your products during shipping to optimizing your supply chain costs, our custom corrugated solutions are designed to meet your specific needs and help your business thrive.

Our commitment to your success includes:

Reducing packaging and shipping costs through optimized design

Protecting your products with custom-engineered solutions

Streamlining your operations with just-in-time delivery

Supporting your growth with scalable production capabilities

Ensuring consistency across every order, large or small

Meeting sustainability goals with eco-friendly materials

Whether you need standard shipping boxes or complex custom designs, we have the expertise and flexibility to deliver packaging solutions that work.

Choose the Right Style for Your Needs

Every product has unique packaging requirements. Our range of corrugated styles ensures you get the perfect balance of protection, cost-efficiency, and functionality. Explore our most popular options below to find the ideal solution for your application.

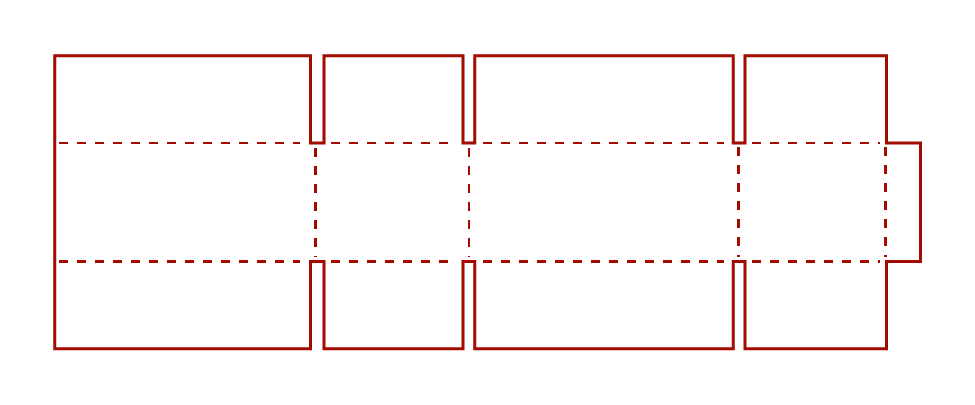

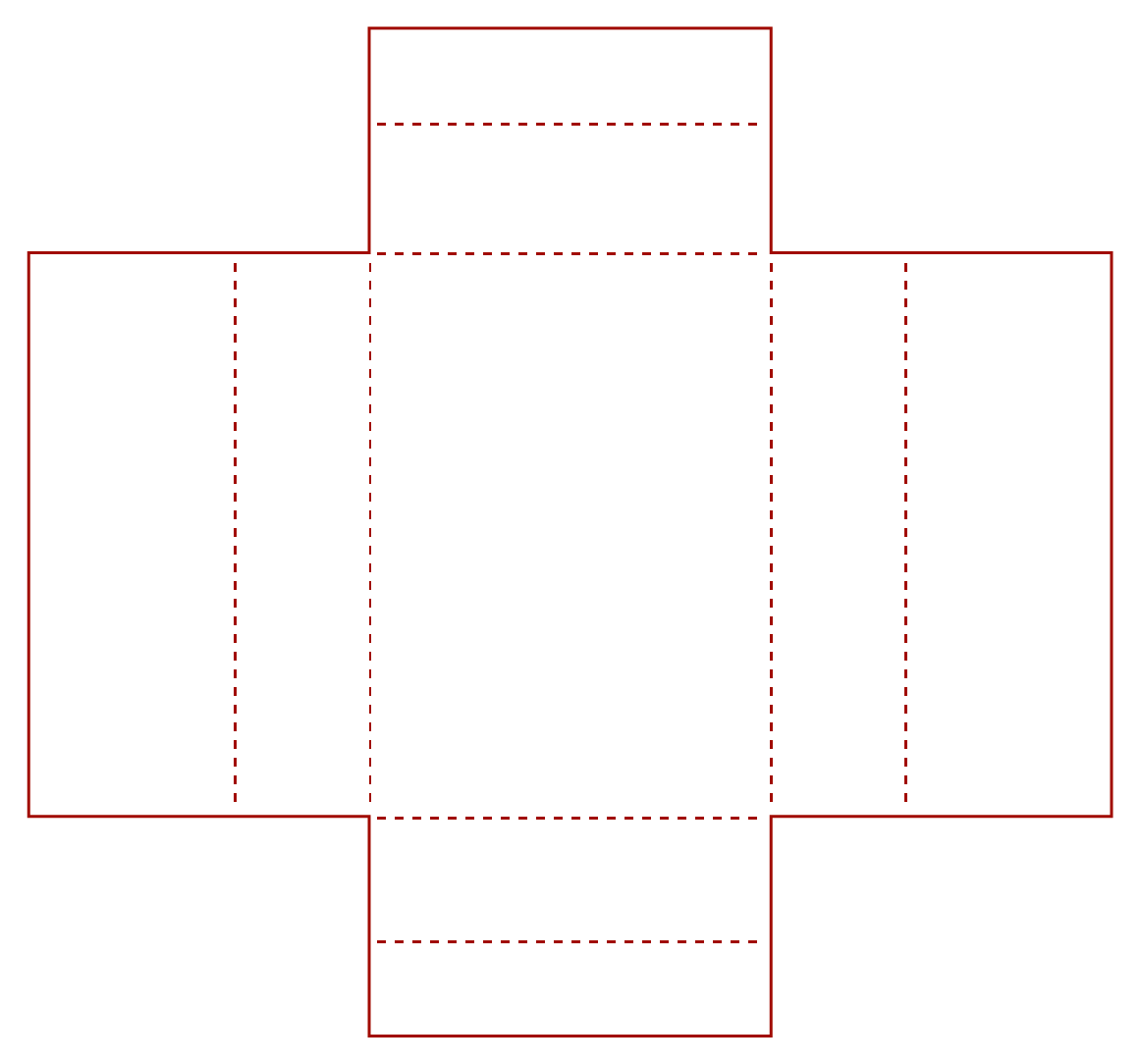

Corrugated Regular Slotted Container (RSC)

Maximum Efficiency

-

All flaps are the same depth, and the two outer flaps (normally the lengthwise flaps) are one-half the container's width, so that they meet at the center of the box when folded. This is a highly efficient design. The only overlaps are the flap for a glued or stitched manufacturer's joint, and the inner (or minor) flaps. There is very little manufacturing waste. The RSC can be used for most products, and is the most common box style. If the product requires a flat, even bottom surface, or the protection of two full layers, a fill-in pad can be placed between the two inner flaps.

-

General shipping, e-commerce fulfillment, standard retail products, warehouse storage

-

Most cost-effective option, minimal material waste, versatile for wide range of applications

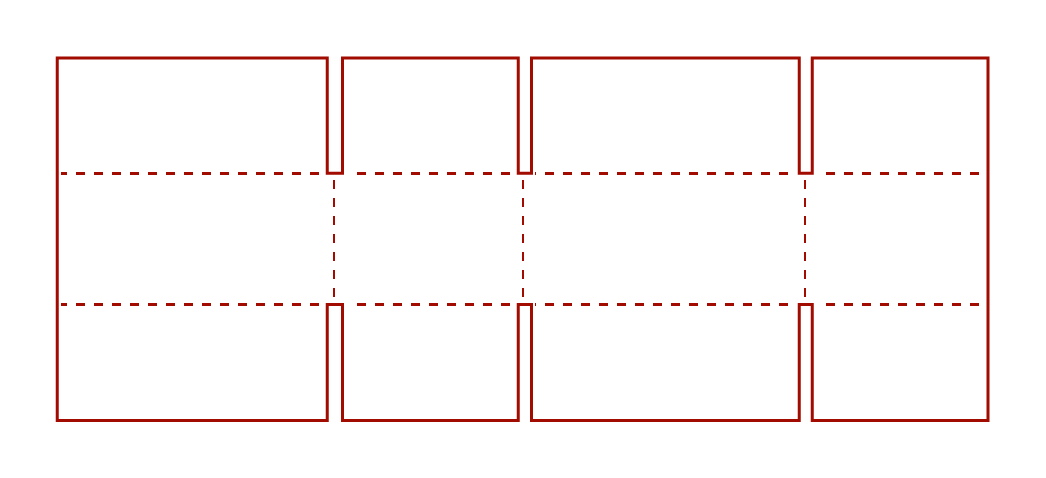

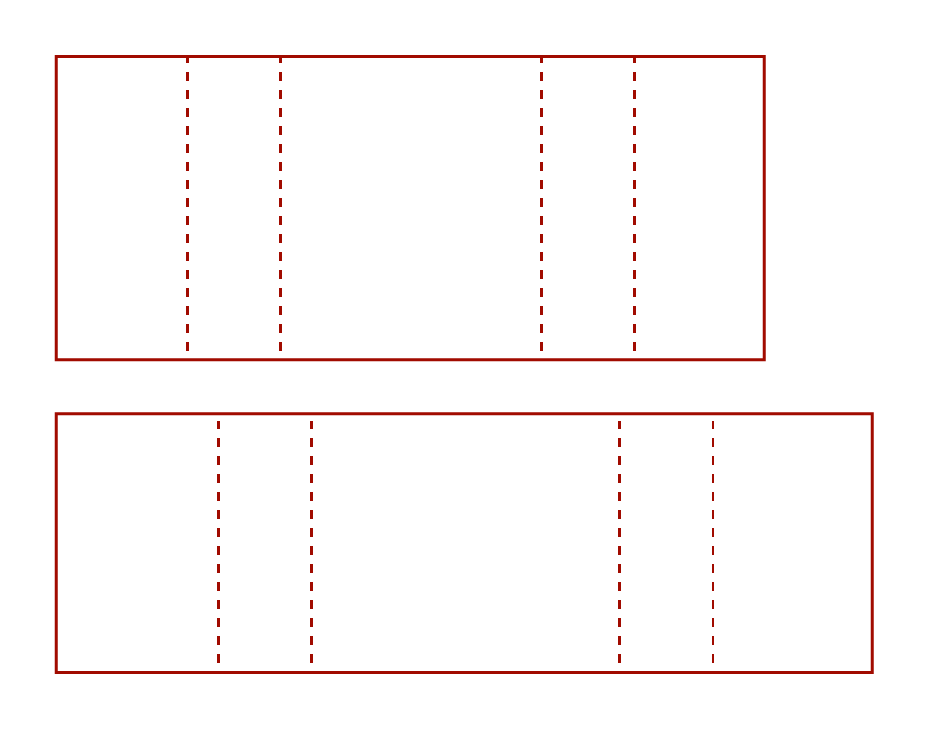

Overlap Slotted Container (OSC)

Extra Security

-

All flaps are the same depth, and the outer flaps overlap by 1 inch or more. The box is easily closed, usually with staples driven through the overlap area. This style is used when the length of the box is considerably greater than the width, resulting in a long gap between inner flaps. The sealed overlap helps to keep the outer flaps from pulling apart.

-

Long, narrow products, electronics, automotive parts

-

Enhanced closure security, prevents flap separation, ideal for elongated items

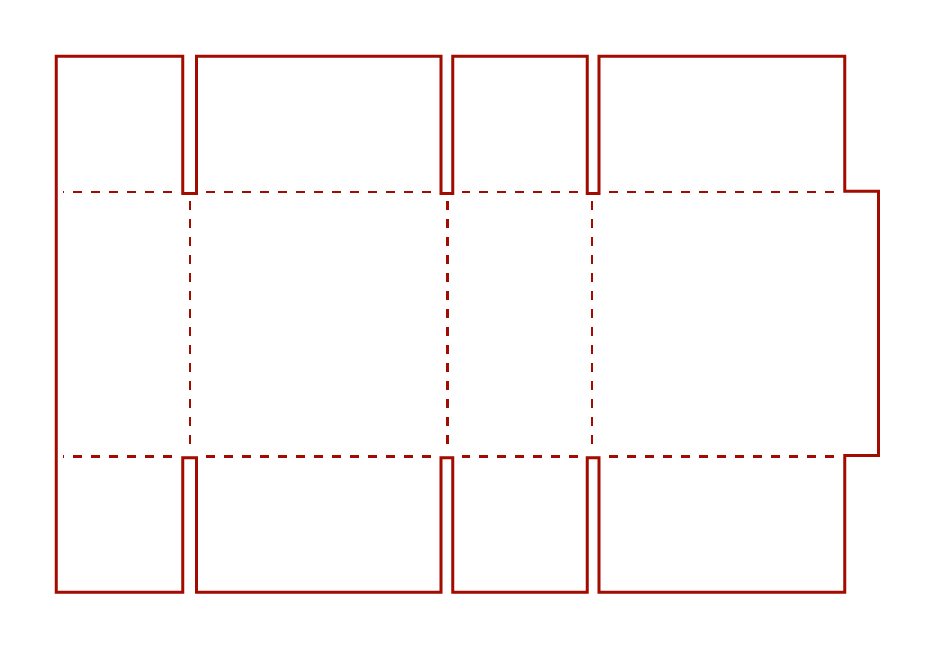

Full-Overlap Slotted Container (FOL)

Maximum Protection

-

All flaps are the same depth, and their depth equals the width of the box. When closed, the outer flaps come within one inch of complete overlap. The style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.

-

Heavy items, rough handling environments, high-stack applications

-

Superior impact resistance, double-layer protection, enhanced stacking strength

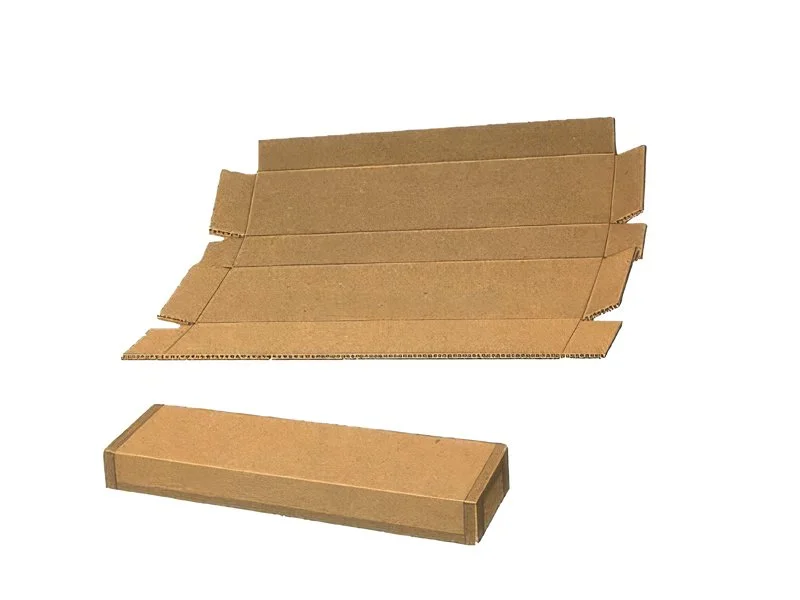

One-Piece Folder Box (OPF)

Streamlined Design

-

One piece of board is cut so that it provides a flat bottom, with flaps forming the sides and ends, and extensions of the side flaps meeting to form the top. One-, two-, and three-piece folders are used for books and other items shipped in a single unit.

-

Books, documents, flat products, retail packaging

-

Clean presentation, easy assembly, cost-effective for single items

Two-Piece Folder Box (2PF)

Double Protection

-

Two rectangular scored pieces provide a double unbroken layer for the bottom, and a double layer for the top. Flaps of one piece form the sides, and flaps of the second piece form the ends.

-

Fragile items, premium products, gift packaging

-

Enhanced protection, professional appearance, reinforced top and bottom

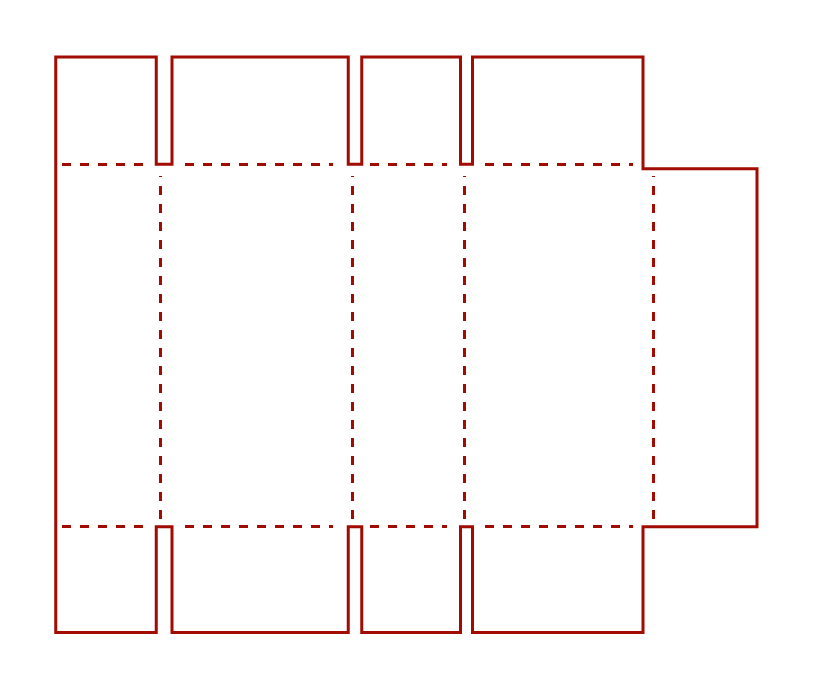

Self-Locking Five-Panel Folder (FPF)

Secure Closure

-

A single cut and scored piece features a fifth panel used as the closing flap, completely covering a side panel. The closed box has several thicknesses in each end, providing stacking strength and protection for long articles of small diameter, which might be damaged, or damage the box, if pushed through ends.

-

Tubes, rods, long narrow items, industrial components

-

No tape required, reinforced ends, prevents product damage from end impact

Ready to Move Forward?

Our packaging experts are standing by to discuss your project requirements, provide technical specifications, and deliver a comprehensive proposal tailored to your needs.

Or call 413.593.1482 to speak directly with our packaging experts